The evolution and impact of twistlocks in shipping

In the world of transport and logistics, twistlocks play a crucial role as mechanical locks that form the foundation for safe and efficient goods transportation. These ingenious devices, featuring a cylindrical metal pin with threads and a rotating mechanism at the end, are used in various sectors to securely fasten loads during transportation.

What exactly are twistlocks?

Twistlocks are versatile locking devices, featuring a central cylindrical pin that can be twisted to either secure or release it. The outer threads enable the safe connection of containers, vehicles, or other loads, making it possible to stack them securely or attach them to various modes of transportation.

Their function: safety and stability

The primary function of twistlocks is to ensure the stability and safety of loads, especially in the context of containerization. When stacking standardised containers on ships, trucks, or trains, these locks serve as indispensable links that lock the containers together. This not only prevents shifts during transportation but also guarantees a standardised and secure method of loading and unloading.

Diversity in locks: from standard to specialised

The fascinating aspect of twistlocks lies in the variety of types developed to meet different needs. Standard twistlocks are commonly used for general container transport, but specialised variants, such as tank twistlocks for securing liquid containers or rail twistlocks for use on trains, illustrate the versatility of these locking systems.

In addition, there are hydraulic twistlocks that use hydraulic pressure for faster and easier locking. This variety of twistlocks reflects the ongoing innovation within the industry, where technology and design are adapted to specific transportation needs.

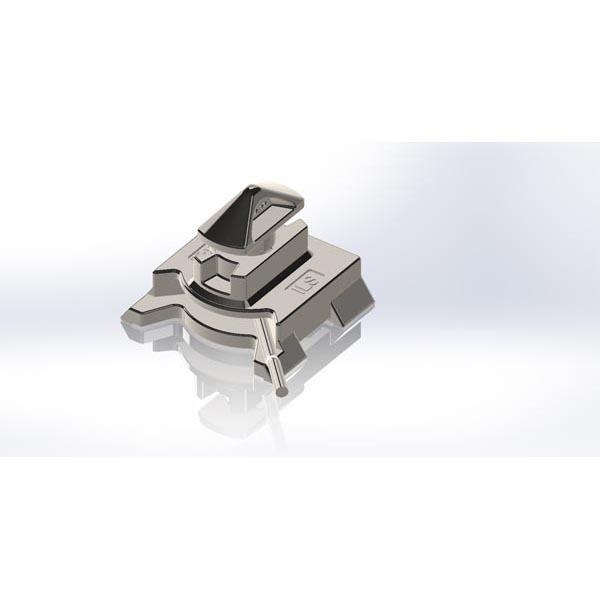

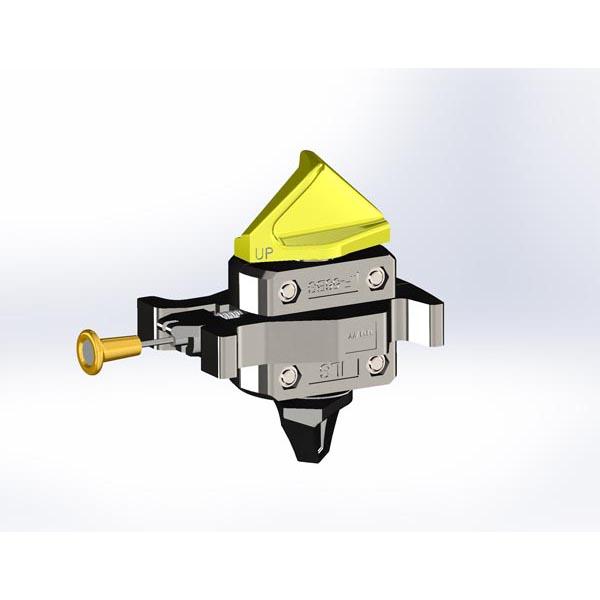

Overview of most essential twistlocks

Importance in the shipping industry

Twistlocks as anchors of containerization

In the dynamic world of the shipping industry, twistlocks have played a central role in transforming how containers are loaded, transported, and unloaded. Their importance can be understood by examining how these intelligent locking systems have facilitated the loading and unloading of containers and contributed to the exponential growth of containerization.

Facilitating loading and unloading

Twistlocks have revolutionised the loading and unloading of containers on ships. Before the 20th century, maritime trade was a patchwork of various packaging formats. Barrels, crates, and sacks were employed to transport goods across oceans. A noticeable lack of standardisation characterised this period, and securing loads on ships was a challenge without uniform methods.

With twistlocks, containers can be quickly and securely locked together, significantly speeding up the loading process. This has not only improved operational efficiency but also reduced the costs of loading and unloading.

Securing cargo at sea

Container ships, often carrying large numbers of containers, must navigate the sea under varying weather conditions. Twistlocks play a critical role in maintaining the stability of stacked containers during these journeys. By securely locking containers together, twistlocks minimise the risk of shifts or loss of cargo during rough sea conditions. This enables ships to operate more safely and efficiently, even in challenging maritime conditions.

Contribution to the growth of containerization

However, this maritime chaos underwent a seismic shift in the 1950’s with the advent of the modern shipping container, pioneered by the visionary American transport entrepreneur Malcolm McLean. As containers could be stacked quickly and securely, the concept of standardised containers became even more appealing to shipping companies. This allowed ships not only to transport more goods but also to load and unload in a standardised and efficient manner at various ports worldwide.

As container transport gained traction, the need for a secure and efficient method of fastening these containers arose. The solution came in the form of twistlocks, an ingenious mechanism to attach containers to each other and to the ship. The simplicity and reliability of these locks quickly made them the industry standard.

Twistlocks were not just a technological addition to shipping; they formed an essential link in the chain of containerization, making it possible to transport goods on a large scale and globally. Their impact on the shipping industry is undeniable and remains a fundamental element in the modern logistics world.

Innovations in locking technology: moving toward automation

With the ongoing evolution of the shipping industry, new technologies are introduced to increase efficiency and improve safety. A notable development within the realm of locking containers is the introduction of Semi Automatic Twistlocks (SATLs). This innovation has simplified the process of locking and unlocking containers on ships. While SATLs have managed to reduce costs, they still require manual effort for placing and removing twistlocks and haven’t completely solved safety concerns.

The industry is moving towards automation with the introduction of Automated twistlock handling stations. However, challenges in technology and economics have limited widespread implementation. Despite this, the industry remains committed to achieving full automation to improve efficiency and decrease dependence on manual processes.

Navigating tomorrow’s seas

Looking at how twistlocks have evolved and influenced shipping, it’s clear that these clever locks go beyond just connecting things—they serve as the foundation for safety, efficiency, and transformation. Starting as reliable fasteners for transporting goods, they’ve become crucial in the remarkable growth of containerization, leaving a lasting impact on the maritime industry.