Twistlocks

Twistlocks

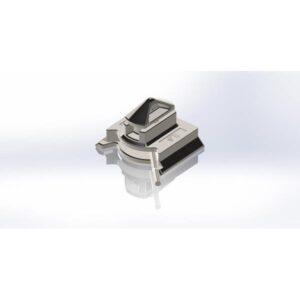

A twistlock is a mechanical fastener used to lock a container in place on a vessel. There are different types of twistlocks with different applications and features. For example, you can choose between left-closing and right-closing variants. These products are manufactured from high-quality galvanised steel, so they are protected against weather and sea water.

Twist lock container

A twistlock can be used to secure containers and swap bodies. This twistable, conical pin is specially designed for this purpose. Containers have attachment points at every corner. The twist lock fits precisely into these, allowing containers to be secured on the ship and then stacked and locked vertically. The twist lock features precise dimensions, making them an excellent fit on a standard ISO shipping container. The lasher’s job is to place twist locks and turn the lever. This can also be done automatically when placing, if automatic rotary lock is chosen.

Twistlocks

Twistlocks are available in both left- and right-closing variants. In a left-closing variant, the lever is on the right in the open position. The lever is closed to the left after placing the containers, after which the twistlock is locked. The right-closing variant has a lever that is on the left when open and closes to the right. For use, it does not matter whether you choose a left- or right-closing twistlock. This depends on your own preferences. For stacking containers, it is often chosen to close all levers inwards. In this case, two left-closing and two right-closing twistlocks are needed to stack two containers. You can also consider purchasing only twistlocks with the same closure, so sorting is not necessary as the locks are fully interchangeable. This saves time and minimises the risk of mistakes.

Standard twist lock

The fascinating aspect of twistlocks lies in the variety of types developed to meet different needs. Standard twistlocks are commonly used for general container transport, but specialised variants, such as tank twistlocks for securing liquid containers or rail twistlocks for use on trains, illustrate the versatility of these locking systems.

Hydraulic twist lock

In addition, there are hydraulic twistlocks that use hydraulic pressure for faster and easier locking. This variety of twistlocks reflects the ongoing innovation within the industry, where technology and design are adapted to specific transportation needs.

Dovetail twistlock

In addition to manual and semi-automatic twistlocks, we also offer dovetail twistlocks. Dovetail twistlocks are used for easily and securely attaching bottom containers to hatch covers. These locks are very useful for customising containers for different applications.

Need help making your choice? Contact us. We will be happy to help you find the suitable twistlocks for your situation.

More about twistlocks

In the world of transport and logistics, twistlocks play a crucial role as mechanical locks that form the foundation for safe and efficient goods transportation. These ingenious devices, featuring a cylindrical metal pin with threads and a rotating mechanism at the end, are used in various sectors to securely fasten loads during transportation.

The primary function of twistlocks is to ensure the stability and safety of loads, especially in the context of containerization. When stacking standardized containers on ships, trucks, or trains, these locks serve as indispensable links that lock the containers together. This not only prevents shifts during transportation but also guarantees a standardized and secure method of loading and unloading.

Facilitating loading and unloading

Twistlocks have revolutionised the loading and unloading of containers on ships. Before the 20th century, maritime trade was a patchwork of various packaging formats. Barrels, crates, and sacks were employed to transport goods across oceans. A noticeable lack of standardisation characterised this period, and securing loads on ships was a challenge without uniform methods.

With twistlocks, containers can be quickly and securely locked together, significantly speeding up the loading process. This has not only improved operational efficiency but also reduced the costs of loading and unloading.

The journey of twistlock production

Twistlocks, often unnoticed but indispensable in the world of safe goods transportation by sea. These small yet powerful mechanisms form the backbone of the logistics industry, where precision and reliability as the most important aspect, are key to success. Let’s take a look behind the scenes of the production process of twistlocks and discover the craftsmanship behind these seemingly simple devices.

Step 1: Design and specification

In the ongoing evolution of the twistlock, spanning over 50 years, continuous

improvements are being made to its design. Innovations focus on achieving sustainability, reduced weight, lower costs, and improved ergonomics. This progressive journey has seen the transition from manual to semi-automatic, and now to full automatic systems, ensuring higher operational reliability and certification by renowned Notified Bodies.

During the engaging design phase of a twistlock, these advancements are seamlessly integrated. Specifications and requirements act as the guiding principles, fostering both creativity and practicality. Factors like load capacity, dimensions, and material selection are meticulously considered.

Step 2: Material sourcing and preparation

Strength, durability, and user-friendliness stand as the three pillars supporting the design. It must withstand the heaviest loads, endure the trials of time, and offer seamless operation for those who rely on it. This is no simple task, it’s a craft shaped by expertise.

In the crucial phase of material selection for a twistlock, the choice of steel, which has remained the same for years, represents a simple yet optimal balance between the required specifications and cost. Every aspect of this material contributes to the integrity and reliability of the final product.

High-quality steel, chosen for its optimum balance of requirements and cost, often takes center stage in this decision. With its unparalleled strength and toughness, it forms the backbone of the twistlock, effortlessly bearing the cargo’s weight and defying the passage of time.

Step 3: Crafting safety and reliability

In the manufacturing process, the twistlock comes to life with precision and expertise. Amidst machinery and skilled labor, safety and reliability take shape.

It begins with the careful shaping of steel, the core material of the twistlock, through processes like forging and casting. Each step is performed with meticulous attention to detail, ensuring that every piece fits seamlessly into the design during assembly.

Then, components undergo cone forging, where the core of the twistlock, known as the cone, is formed by pressing steel blocks with forces up to 1000 tons. This process ensures the strength and integrity of this crucial component.

Next, the two halves of the twistlock body are made through a casting process. This process shapes the essential parts of the twistlock, ensuring they are robust and reliable.

Following this, various components of the twistlock are formed through forging and pressing. Raw materials are transformed into functional parts, each crafted with care to meet the design requirements. After formation, the components are galvanized for enhanced durability, and the top cone is painted yellow, adding an extra layer of protection and visibility.

In the subsequent assembly stage, experienced workers meticulously put together all the components. They incorporate standard items such as steel wires, springs, bolts, and nuts. Each connection is made purposefully, using techniques like bolting, to create a sturdy and durable twistlock. In production, they use industrial assembly tables equipped with calibrated pneumatic tools, ensuring that every bolt is tightened with the same precise force,

a point of pride in the manufacturing process.

Throughout the manufacturing process, quality checks are conducted to ensure that each component meets the necessary standards of safety and performance. Only when these checks are passed does the twistlock become ready to fulfill its role with confidence and reliability.

Step 4: Rigorous testing for quality assurance

In the final crucial phase of testing and quality assurance, the twistlock undergoes a comprehensive series of tests and checks, where every aspect of its integrity and performance is meticulously evaluated. No detail is overlooked, and no compromise is made on quality.

Load tests, torsion tests, and durability tests form the backbone of this process. The twistlock is subjected to extreme forces, carefully assessing its ability to bear loads and withstand the passage of time. It is only through these rigorous trials that the assurance of meeting the stringent requirements placed upon it can be guaranteed.

To ensure compliance with the certification criteria of DNV, 2% of all produced items are tested on proofload. This stringent sampling method ensures that each batch meets the highest standards of quality and reliability.

But it goes beyond sheer strength alone. Visual inspections and dimensional checks are conducted with keen attention to detail, striving for perfection. Every weld point, every angle, every millimetre is thoroughly scrutinized, searching for any manufacturing flaws that could compromise the integrity of the twistlock. And where necessary, corrective measures are taken, ensuring that every unit leaving the factory is of impeccable quality.

Step 5: Final preparations

In the final step of the process, where care and precision converge, the twistlock is prepared for its journey to its destination.

It begins with packaging, a meticulous wrapping that shields the twistlock from the harsh elements of transportation. Each piece is packed with care, with attention to detail and sturdiness to ensure it arrives safely and undamaged at its destination. For it is only through this careful preparation that the twistlock can fulfil its task of securely and efficiently anchoring the cargo.

But packaging is more than just protection, it is also an opportunity to leave a lasting impression. Each package is infused with the hallmark of craftsmanship and quality, serving as a reminder of the promise of excellence that the twistlock represents.

Yet, the task is not yet complete. In addition to the twistlock itself, the necessary documentation is also carefully prepared. Product certificates and user manuals are included, so that customers and end-users can confidently use the twistlock, knowing that it meets the highest standards of safety and performance.

Step 6: Feedback and continuous improvement

Gathering feedback from end-users is crucial to understanding how twistlocks perform in real-world scenarios. By actively listening to the experiences and challenges faced by those who interact with twistlocks daily, manufacturers gain valuable insights into usability, reliability, and durability. This direct feedback loop allows for informed decisions in enhancing future iterations of twistlock designs.

Utilising the insights garnered from customer feedback, manufacturers embark on a journey of continuous improvement. Each suggestion, critique, and observation serves as a catalyst for refining design elements, optimising material selection, and streamlining manufacturing processes. Through this iterative approach, every batch of twistlocks undergoes enhancement, ensuring that subsequent versions surpass previous ones in functionality, resilience, and end-user satisfaction.